- Home

- SA

SA

Burs / SA

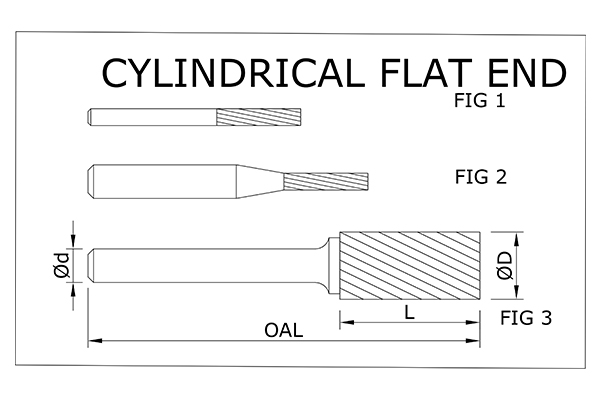

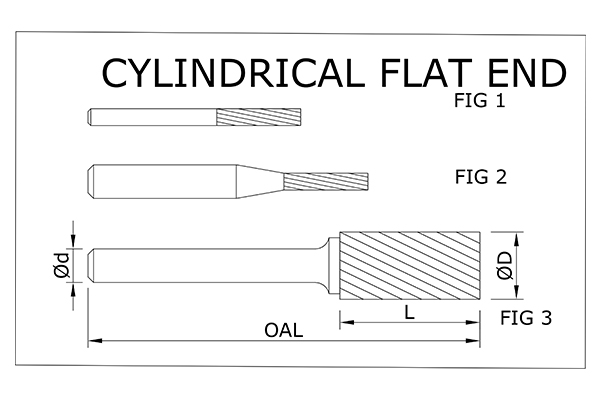

Cylindrical Flat End Shape

- Shape code: USCTI – SA, ISO – ZYA, India - A

- Both inch and metric dimensions are available as standard

- Construction of the carbide burr – All sizes 6mm / 1/4 inch and below are available in solid carbide. All other sizes are from brazed construction

- Carbide burrs are available with a variety of cuts like – Single cut (Z3), Double Cut (ZX/Z4/Z7), Diamond Cut (Z6), NF Cut (Z1/Z2), Aluminum Cut (Z9), Fine Cut (Z5), Steel & INOX Cut (Z42)

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| A0312 | 3 | 15 | 3 | 38 | Solid, Fig 1 |

| A06M | 6 | 12 | 3 | 50 | Brazed, Fig 3 |

| A0414 | 4 | 15 | 6 | 65 | Brazed, Fig 2 |

| A06 SC | 6 | 15 | 6 | 50 | Solid, Fig 1 |

| A0616 | 6 | 15 | 6 | 65 | Brazed, Fig 3 |

| A0616L20 | 6 | 20 | 6 | 70 | Brazed, Fig 3 |

| A0820 | 8 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1022 | 10 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1222 | 12 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1225 | 12 | 25 | 6 | 75 | Brazed, Fig 3 |

| A1640 | 16 | 25 | 6 | 75 | Brazed, Fig 3 |

Carbide burrs (Z3 Cut) are general-purpose tools designed for cast iron, steel, some copper and brass, and other ferrous materials. Single cut tools give good material removal and good workpiece finish. Single cut burrs have multiple teeth following the same spiral angle along the axis of the tool. This cut generates longer chips. It is the most popular cut in India.

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| A0312DC | 3 | 15 | 3 | 38 | Solid, Fig 1 |

| A06M DC | 6 | 12 | 3 | 50 | Brazed, Fig 2 |

| A0414 DC | 4 | 15 | 6 | 65 | Brazed, Fig 3 |

| A0616 SC DC | 6 | 15 | 6 | 50 | Solid, Fig 1 |

| A0616 DC | 6 | 15 | 6 | 65 | Brazed, Fig 3 |

| A0616L20 DC | 6 | 20 | 6 | 70 | Brazed, Fig 3 |

| A0818 DC | 8 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1020 DC | 10 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1222 DC | 12 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1225 DC | 12 | 25 | 6 | 75 | Brazed, Fig 3 |

| A1640 DC | 16 | 25 | 6 | 75 | Brazed, Fig 3 |

Carbide burrs (Z4/Z6/Z7 Cut) allow for rapid stock removal in harder / tougher materials like steel and its alloys, stainless steel etc. The addition of the left-hand spiral flutes breaks the chip while cutting thereby allowing for decreased vibration, better operator control and comfort. As the cutting forces get reduced problems associated with teeth breakage are eliminated. Double cut burrs can be used at slower than normal speeds. Double Cut is the most common cut throughout the world.

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| AD-03-2 | 3 | 15 | 3 | 38 | Solid, Fig 1 |

| AD-04-2 | 4 | 15 | 6 | 65 | Brazed, Fig 2 |

| AD-06-2 SC | 6 | 15 | 6 | 50 | Solid, Fig 1 |

| AD-06-2 | 6 | 15 | 6 | 65 | Brazed, Fig 3 |

| AD-08-2 | 8 | 20 | 6 | 70 | Brazed, Fig 3 |

| AD-10-2 | 10 | 20 | 6 | 70 | Brazed, Fig 3 |

| AD-12-2 | 12 | 20 | 6 | 70 | Brazed, Fig 3 |

| AD-12-2 | 12 | 25 | 6 | 75 | Brazed, Fig 3 |

| AD-16-2 | 16 | 25 | 6 | 75 | Brazed, Fig 3 |

Carbide burrs (Z6 Cut) are similar to double cut burrs except that the left-hand spiral patterns are very close together to form a cutting tooth to look like a pyramid / diamond. The diamond cut is very effective in heat treated and tough alloy steels, producing extremely small chips. It offers very good operator control with good stock removal at the sacrifice of workpiece surface finish.

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| A0616 NF | 6 | 15 | 6 | 65 | Brazed, Fig 3 |

| A0820 NF | 8 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1022 NF | 10 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1222 NF | 12 | 20 | 6 | 70 | Brazed, Fig 3 |

| A1225 NF | 12 | 25 | 6 | 75 | Brazed, Fig 3 |

Carbide burrs (Z1 & Z2 Cut) have teeth like a single cut burr – but with coarse / fewer teeth. This cut finds applications for deburring softer metals – like bronze, brass, aluminum etc. It is a rudimentary enhancement over a single cut. It has a very high material removal rate. It has been replaced by ALU Cut in advanced industries – which cuts better and leaves a better surface finish on the workpiece.

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| SA-1M ALU | 6 | 16 | 6 | 50 | Solid, Fig 1 |

| SA-3M ALU | 9.5 | 19 | 6 | 63 | Brazed, Fig 3 |

| SA-5M ALU | 12.7 | 25 | 6 | 69 | Brazed, Fig 3 |

| SA-6M ALU | 16 | 25 | 6 | 69 | Brazed, Fig 3 |

Carbide burrs (Z9 / ALU) are the best burrs for Aluminum and other soft materials. Burrs with this cut have 6-8 teeth and feature a relief / facet grind at the cutting edge. The teeth design ensures almost no clogging of the material being cut inside the teeth and easy evacuation of the chip. The surface finish on the workpiece is very good. These burrs look like mini milling cutters in their design and are solely made on CNC grinders.

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| SA-1M STEEL | 3 | 13 | 3 | 38 | Solid, Fig 2 |

| SA-2M STEEL | 6 | 19 | 6 | 50 | Brazed, Fig 3 |

| SA-3M STEEL | 8 | 19 | 6 | 65 | Brazed, Fig 3 |

| SA-5M STEEL | 10 | 19 | 6 | 65 | Brazed, Fig 3 |

Carbide burrs (Z42 Cut) provide extremely fast material removal – up to even 100% when compared with double cut burrs – in steel and cast steel. The coarse teeth design with relief cleanly cuts off the workpiece and evacuates the chip better. Steel cut carbide burrs reduce operator fatigue due to lower vibration. These burrs cannot be used with hard materials. These burrs look like mini milling cutters in their design and are solely made on CNC grinders.

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| SA-43M INOX | 3 | 13 | 3 | 38 | Solid, Fig 1 |

| SA-1M INOX | 6 | 19 | 6 | 50 | Solid, Fig 1 |

| SA-2M INOX | 8 | 19 | 6 | 65 | Brazed, Fig 3 |

| SA-3M INOX | 10 | 19 | 6 | 65 | Brazed, Fig 3 |

| SA-5M INOX | 12 | 25 | 6 | 70 | Brazed, Fig 3 |

Carbide burrs (Z42 Cut) are specifically designed for extremely aggressive material removal rates – up to 100% when compared to double cut burrs – in INOX or Stainless Steel. The coarse teeth design with relief cleanly cuts off the workpiece and evacuates the chip better. INOX cut carbide burrs reduce operator fatigue due to lower vibration. These burrs cannot be used with hard materials. These burrs look like mini milling cutters in their design and are solely made on CNC grinders.