- Home

- SK

SK

Burs / SK

Cone 90 Degree Shape

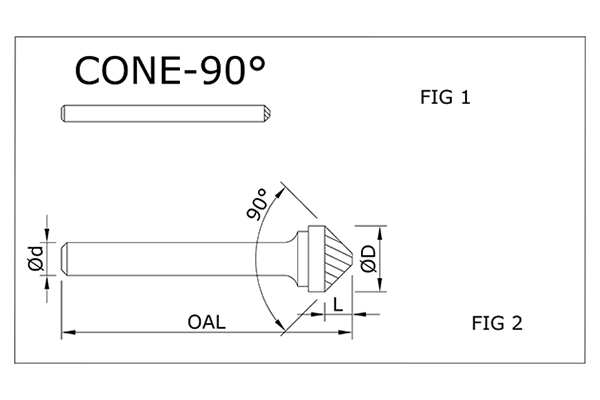

- Shape code: USCTI – SK, ISO – ZYA, India - A

- Both inch and metric dimensions are available as standard

- Construction of the carbide burr – All sizes 6mm / 1/4 inch and below are available in solid carbide. All other sizes are from brazed construction

- Carbide burrs are available with a variety of cuts like – Single cut (Z3), Double Cut (ZX/Z4/Z7), Diamond Cut (Z6), NF Cut (Z1/Z2), Aluminum Cut (Z9), Fine Cut (Z5), Steel & INOX Cut (Z42)

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| H 1224 | 12 | 11 | 6 | 61 | Brazed, Fig 3 |

| H 1624 | 16 | 13 | 6 | 63 | Brazed, Fig 3 |

Carbide burrs (Z3 Cut) are general-purpose tools designed for cast iron, steel, some copper and brass, and other ferrous materials. Single cut tools give good material removal and good workpiece finish. Single cut burrs have multiple teeth following the same spiral angle along the axis of the tool. This cut generates longer chips. It is the most popular cut in India.

| Code | Tip Dia | Tip Length | Shank Dia | OAL | Construction |

|---|---|---|---|---|---|

| SK-42M DOUBLE | 3 | 1.5 | 3 | 38 | Solid, Fig 1 |

| SK-1M DOUBLE | 6 | 3 | 6 | 50 | Solid, Fig 1 |

| SK-3M DOUBLE | 9.5 | 4.7 | 6 | 52 | Brazed, Fig 3 |

| SK-5M DOUBLE | 12.7 | 6.3 | 6 | 54 | Brazed, Fig 3 |

| SK-6M DOUBLE | 16 | 8 | 6 | 57 | Brazed, Fig 3 |

Carbide burrs (Z4/Z6/Z7 Cut) allow for rapid stock removal in harder / tougher materials like steel and its alloys, stainless steel etc. The addition of the left-hand spiral flutes breaks the chip while cutting thereby allowing for decreased vibration, better operator control and comfort. As the cutting forces get reduced problems associated with teeth breakage are eliminated. Double cut burrs can be used at slower than normal speeds. Double Cut is the most common cut throughout the world.

Carbide Burrs in this shape are not available.

Carbide Burrs in this shape are not available.

Carbide Burrs in this shape are not available.

Carbide Burrs in this shape are not available.

Carbide Burrs in this shape are not available.